High Frequency

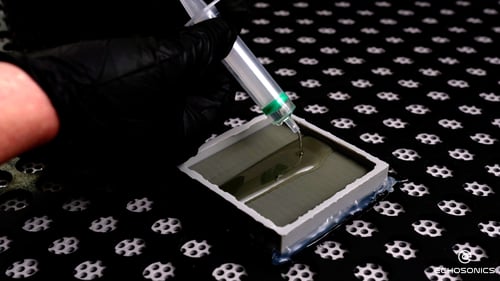

Composite Transducer Manufacturing

Utilizing the latest technology for Sonar, Medical, and NDT ultrasound applications.

Proud to supply these brands:

Transducers for Sonar Technology

At Echosonics we have access to the latest Dicing and Grinding Technology and with our continued investment in equipment for the manufacturing of High Frequency Fine Pitch PZT 1-3 Composite design. Offering a range of PZT Materials from PZT4 Navy I, PZT5 Navy Type II, PZT8 Navy Type III to PZT5H Navy Type VI and others on request, High Resolution SONAR Market applications include Naval Defence and Commercial, Police/Fire Department Search and Rescue, Harbour Surveillance, Commercial Fishing, ROV’s, Including Hydrographic, Oceanographic and Environmental Science Sectors.

Medical Ultrasound Solutions

We have the capability for manufacturing fine diced pillars/kerfs for high frequency composites to support the ongoing growth for medical transducers supporting the High MHz range of frequency operation above 20MHz for high-resolution imaging. With the support and capability to also supply lower frequency 1-3 composite and bulk PZT components for the Therapeutic applications and HIFU (High intensity Frequency Ultrasound) applications.

Side Scan Ceramic

At Echosonics we have access to the latest Dicing and Grinding Technology and with our continued investment in equipment for the manufacturing of High Frequency Fine Pitch PZT 1-3 Composite designs. Offered in a range of PZT Materials to build to print or custom requirements. High Resolution SONAR Market applications include Naval Defence and Commercial, Police/Fire Department Search and Rescue, Harbour Surveillance, Commercial Fishing, ROV’s, Including Hydrographic, Oceanographic and Environmental Science Sectors.

Bespoke Ceramic Manufacturing/Shapes

We have the capability to support in house sub-contract 1-3 Composite dicing and filling to customer specifications and drawings, including the capability to produce PZT Bulk Ceramic Plates and Bars, Custom Dimensions for Ring and Disc shaped components can be supplied on request. Our inhouse capability for Electroding/Annealing/Polarisation and Testing offers to support SONAR, Medical and UDT applications, other application requests will be reviewed based upon component requirements.

With ongoing investment into R&D Echosonics will continue to grow our bespoke capabilty, assembly and electronic connection techniques within our growing portfolio of manufacturing capabilities, in order to support and grow along with our customers’ needs, requirements and expectations.

Why we are different

Cutting-Edge Technology

At Echosonics, we use the latest technology for Sonar, Medical, and NDT ultrasound applications. Our advanced transducer research and development ensures that our customers benefit from cutting-edge technology and solutions.

Exceptional Quality

We take pride in delivering products of exceptional quality. Our team of experts at Echosonics ensures that each product meets the highest standards of performance and reliability, providing our customers with the best possible experience.

Bespoke Service

Our dedicated team collaborates closely with each customer, crafting bespoke transducers tailored to their unique product needs and applications. With more than three decades of experience in ceramic manufacturing, our expertise is unparalleled.